Water Treatment Facility

Need for Improvements

Prior to 2010, the City of Washburn operated a 500 gallon per minute (gpm) conventional water treatment facility. The facility was originally constructed in the mid1970’s to provide potable water for the citizens of Washburn. In 2004, the City retained the services of Advanced Engineering and Environmental Services, Inc. (AE2S) to complete a master plan of the treatment facility and water distribution system. The master plan evaluated the capacity of the existing facility to meet current and future demands (including the City of Washburn and a portion of the McLean Sheridan Rural Water District), condition of each treatment component, and the ability of the facility to meet regulatory requirements.

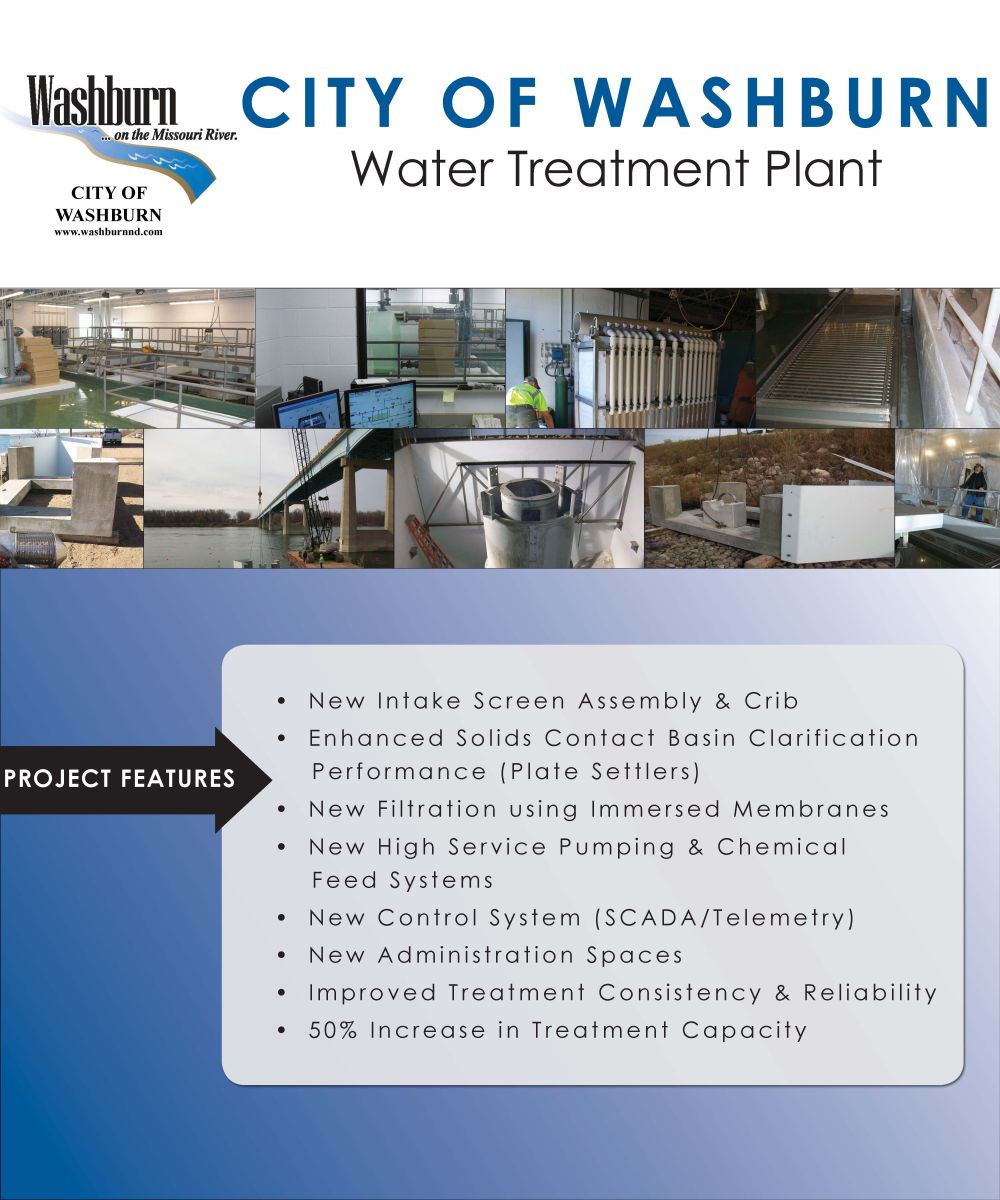

To address the findings of the evaluation and the recommendations of the master plan, the City elected to pursue a water treatment plant optimization project. The project included optimization of the raw water intake, rehabilitation of the solids contact basins, conversion of the conventional filters to immersed membrane filters, new chemical feed systems, new high service pumps, new electrical and control systems, and various other related system improvements. The optimization improvements increased the capacity of the facility from 500 gpm to 1,200 gpm, and provides the City with a state of the art facility capable of producing very high quality of finished water.

Detailed Optimization Improvements

The raw water intake improvements included an extension of the existing intake piping and the installation of a screen and protective structure in the Missouri River. The new intake screen helps to keep larger particles from entering the facility from the river. In addition, the new raw water pumps were installed to transfer the water to the treatment facility.

The raw water from the intake is sent to the refurbished solids contact basins. The original basins were removed from service to allow new equipment to be installed. The refurbished solids contact basins are used to clarify the water by settling the heavier solids. A chemical is added to help settle the larger particles to the bottom of the basin, while the clarified (clean) water rises to the top.

Following clarification, the water is sent directly to filtration. The original granular media filters were replaced with immersed membrane filters. The immersed membranes were selected to provide additional treatment capacity, without increasing the footprint of the filters. In addition, the new membrane treatment technology also provides additional disinfection credit for regulatory compliance. The upgraded facility contains three filter trains, each capable of producing up to 600 gpm. All new process piping, controls, and ancillary equipment were also installed during the rehabilitation of the filters.

After filtration, the water is disinfected using liquid chlorine. The chlorine is dosed into the filtered water prior to it entering the water storage clearwell. Fluoride is also added at this point to assist in the prevention of tooth decay. From the clearwell, water is pumped to the distribution system, through two sets of newly installed high service pumps. The City utilizes three elevated water towers to provide storage for consumer demand as well as to provide adequate fire protection for the community.

Additional improvements included during the optimization project included: plant-wide electrical and control systems upgrades; new lighting; new coagulant, chlorine, fluoride, and phosphate chemical feed systems; architectural features including a new vestibule, lab, and office area, plant wide painting, and a new membrane roof system.

The funding for the water plant improvements was secured through a combination of grants and low interest loans. To date, approximately 57 percent of the project expenses were paid for using grants from the Municipal, Rural, and Industrial water supply program, the Environmental Protection Agency, and the American Recovery and Reinvestment Act. The remaining 43 percent of the project expenses were paid for using low interest loans, which will be paid back over a 20 year period using water sales revenue.